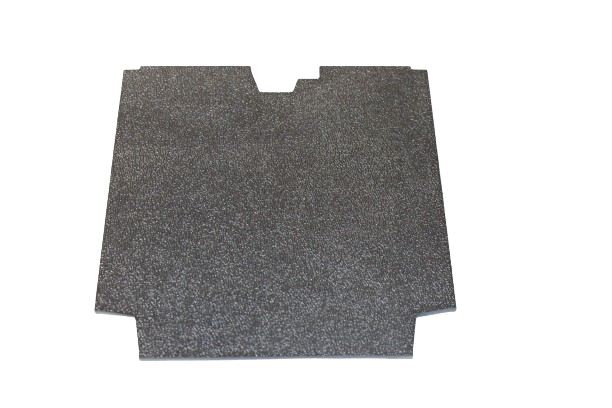

Laser Cut ABS

American Acrylics

Benefits and Applications of Laser Cut ABS

ABS, or Acrylonitrile Butadiene Styrene, is a versatile thermoplastic known for its strength, durability, and impact resistance. The integration of laser-cutting technology into ABS fabrication has opened up new avenues for precision engineering and customization. In this comprehensive guide, we will delve into the myriad benefits and applications of laser cut ABS, shedding light on its pivotal role in industries that demand accuracy, efficiency, and innovation.

Understanding Laser Cut ABS

1.1 Definition and Characteristics:

ABS is a widely used thermoplastic polymer that exhibits excellent mechanical properties, making it suitable for various applications. Laser-cutting technology enhances ABS by allowing precise cutting, engraving, and shaping, unlocking a new level of versatility for this already adaptable material.

1.2 Precision and Customization:

Laser cut ABS offers unparalleled precision, allowing for intricate designs and shapes that were once challenging to achieve. This level of customization is particularly valuable in industries where tailored solutions are essential for optimal performance and aesthetic appeal.

Benefits of Laser Cut ABS

2.1 Precision Cutting:

One of the primary advantages of laser cut ABS is the exceptional precision it offers. Laser technology ensures clean, sharp edges with minimal material waste, resulting in components that meet stringent quality standards and specifications. This precision is crucial in industries where accuracy is paramount.

2.2 Versatility in Design:

Laser cutting allows for intricate and complex designs to be realized on ABS sheets, providing designers with the freedom to create innovative solutions. Whether it’s producing detailed prototypes or crafting bespoke products, laser cut ABS caters to a wide range of design possibilities.

2.3 Cost-Effective Prototyping:

The precision and speed of laser cutting make it a cost-effective method for prototyping with ABS. Designers and engineers can quickly iterate and test their concepts, reducing time-to-market and development costs. This is particularly advantageous in industries where rapid prototyping is a key aspect of the product development cycle.

2.4 Enhanced Efficiency:

Compared to traditional cutting methods, laser cutting is a more efficient process. It reduces production time, increases throughput, and minimizes material waste, ultimately contributing to cost savings and improved operational efficiency in manufacturing processes.

2.5 Minimized Material Waste:

Laser cut ABS produces minimal material waste, optimizing the use of resources. This not only aligns with sustainability goals but also ensures economical use of the material, making laser cut ABS an environmentally conscious choice for industries focused on reducing their ecological footprint.

Applications of Laser Cut ABS

3.1 Prototyping and Product Development:

Laser cut ABS plays a pivotal role in the prototyping and product development phase. Its precision allows for the creation of accurate prototypes, enabling designers and engineers to test and refine their concepts before moving into full-scale production. This is particularly valuable in industries such as consumer electronics, automotive, and consumer goods.

3.2 Signage and Displays:

The versatility of laser cut ABS makes it an ideal material for signage and displays. Whether creating intricate logos, lettering, or three-dimensional displays, laser cut ABS allows for detailed and visually striking results. This application is prevalent in retail, exhibitions, and marketing displays.

3.3 Industrial Components:

In industrial settings, laser cut ABS is used to fabricate components for machinery and equipment. Its strength, impact resistance, and customization capabilities make it suitable for producing parts that withstand harsh conditions. Applications include protective covers, panels, and custom fittings.

3.4 Automotive Interiors and Prototypes:

The automotive industry leverages laser-cut ABS for interior components and prototype development. From intricate dashboard details to customized interior panels, laser-cut ABS allows for precise manufacturing and prototyping, contributing to the overall design aesthetics and functionality of vehicles.

3.5 Electronics Enclosures:

ABS’s electrical insulating properties make it a suitable material for electronics enclosures. Laser-cut ABS allows for the creation of precise and custom enclosures that protect electronic components. This application is crucial in the electronics and telecommunications industries.

Conclusion:

In conclusion, laser-cut ABS stands as a testament to the marriage of precision engineering and versatile thermoplastics. Its benefits, including precision cutting, versatility in design, and cost-effective prototyping, position laser cut ABS as a game-changer in various industries. From prototyping and product development to signage, industrial components, automotive interiors, and electronics enclosures, laser-cut ABS continues to redefine the possibilities of what can be achieved with this durable and adaptable material. As industries continue to evolve, laser-cut ABS remains a key player in shaping the future of manufacturing and design.

American Acrylics

WHY CHOOSE US?

Quality

Experience exceptional quality and satisfaction with our precision custom acrylic products designed to meet your unique needs.

Competitive Prices

Embrace maximum value with our cost-effective selection of options curated to drive your efficiency without compromising on quality or performance.

On-time Delivery

Choose American Acrylics for superior products that not only meet your needs but arrive on time. We take pride in clear communication from our first discussion about your project until your parts arrive according to schedule.